Cotton Yarn Mill

Why Egyptian Cotton

Egyptian cotton has become wildly popular in recent years. Why exactly? Does it really matter?

It was thought for ages that cotton was cotton and thread count was king when choosing quality fabrics. That is no longer true.

Consumer guidelines for buying fabric suggest that cotton from Egypt is superior to other cotton. Is this true and, if so, what is the big difference?

The varieties of Egyptian cotton are used to create fabric of all types from sheets to pillowcases to comforters to shirts. The long staple or long fiber of Egyptian-grown cotton means that there is more continuous fiber to use when creating threads or yarns.

This yarn is smaller in diameter yet stronger than other cottons. Smaller yarn means that more threads per square inch can be used to create stronger fabric which is light in weight yet breathes well.

More threads per inch means that the thread count on the fabric label will be higher. Many buyers think that choosing high thread count sheets is the only gauge of quality. This is not true, but in the case of cotton grown in Egypt, the higher thread count means the fabric will be incredibly strong and will last for years and years. If cared for properly, Egyptian produced cotton fabric can last for decades.

The texture of the fabric created from Egyptian grown cotton is a bit harder than other cottons when the fabric is new. However, with every single laundering, the cotton fabric from Egyptian fibers becomes softer and softer. Like a fine perfume, age improves the Egyptian fiber cotton fabric. Unlike many products, fabric made from Egyptian cotton will become softer with each washing.

Cotton grown in Egyptian fields also produce less lint and therefore will not pill after repeated washings like other materials. At one time, the only way to obtain Egyptian fiber cotton fabrics was to shop in high-end expensive stores. This is no longer true and most department stores and online stores carry a selection of Egyptian produced cotton sheets,shirts and other items for abuyer seeking a high quality product.

Processability

Egyptian cotton is distinct for many reasons; one of them being the supermacyof cellulose distribution in its fibers.

Each cotton fiber is composed of concentric layers. The cuticle layer on the fiber which consists of wax and pectin materials is separated from other fibers. The primary wall, the most peripheral layer of the fiber, is composed of cellulose crystalline fibrils.

The secondary wall of the fiber consists of three distinct layers. All three layers of the secondary wall include closely packed parallel fibrils with spiral winding of 25-35° and represent the majority of cellulose within the fiber. The innermost part of cotton fiber the lumen, is composed cell content remains. Before boll opening, the lumen is filled with liquid containing the cell nucleus and protoplasm. The twists and convolutions of the dried fiber are due to the removal of this liquid. The cross section of the fiber is bean-shaped, swelling almost round when moisture absorption takes place.

The overall contents are broken down into the following components.

- 80 – 90% cellulose.

- 6 – 8% water.

- 0.5 – 1% waxes and fats.

- 0 – 1.5% proteins.

- 4 – 6% hemicellulose and pectins.

- 1 – 1.8% ash.

During scouring, treatment of the fiber with caustic soda, natural waxes and fats in the fiber are saponified and pectins and other non-cellulosic materials are released, so that the impurities can be removed by just rinsing away.

After scouring, a bleaching solution (consisting of a stabilized oxidizing agent) interacts with the fiber and the natural colors removed. Bleaching takes place at an elevated temperature for a fixed period of time.

Mercerization is another process of improving absorption properties of cotton. Cotton fiber is immersed into 18- 25% solution of sodium hydroxide often under tension. The fiber obtains better luster and absorption during mercerization. After scouring and bleaching, the fiber is 99% cellulose. Cellulose is a polymer consisting of anhydroglucose units connected with 1,4 oxygen bridges in the beta position. The hydroxyl groups on the cellulose units enable hydrogen bonding between two adjacent polymer chains.

Fiber properties

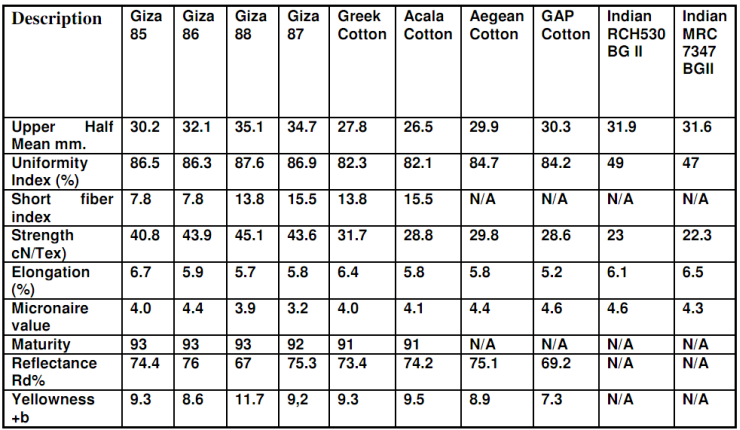

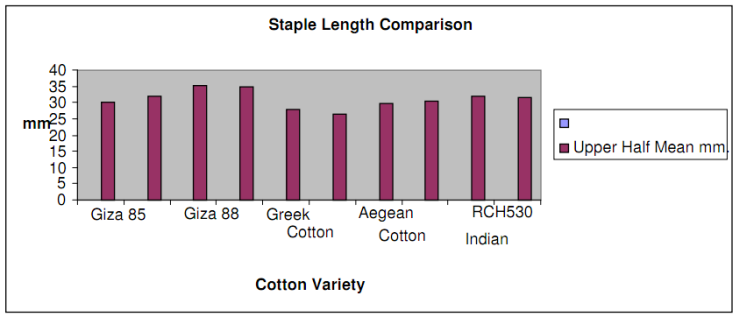

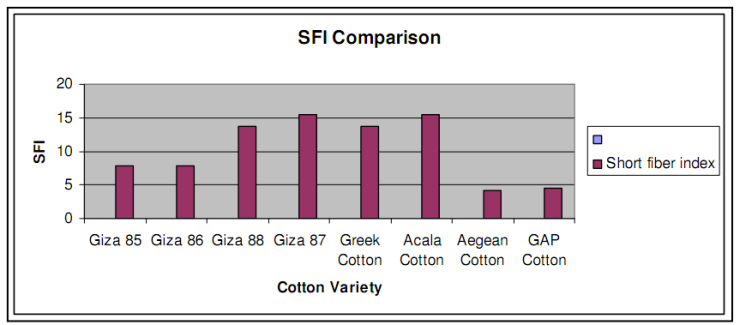

The following table shows the quality properties of different varieties of Egyptian cotton: Giza 85, 86 , 88 and 87 verses Upland Greek cotton, Acala Sudanese cotton, Southern Indian cotton, Aegean and GAP Turkish cotton.

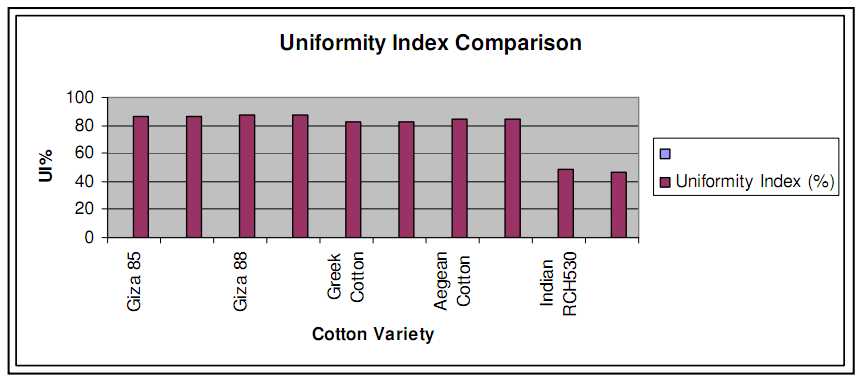

Naturally, the fiber quality of Egyptian cotton variety is higher than all other cotton varieties even if they are comparable in fiber length. The main differences shown include: fiber strength, fiber length, length uniformity, fiber fineness, fiber elongation and short fiber index. In some samples of Greek and Acala cottons the short fiber index reached 18.0 accompanied by the lowest length uniformity of 79.

Fiber Properties for other Egyptian cotton Varieties

Conclusion

- Egyptian Cotton is of superior quality to most of the cotton varieties known in the world concerning all mechanical and technological characteristics.

- Egyptian cotton uniformity is higher than Turkish cotton uniformity including comparable micronaire and staple length values. Due to cellulose uniformity in fibers, Egyptian cotton is superior for comfort performance products, such as shirting, bedding and even towels.

- Egyptian cotton strength is almost 50% higher than Greek and Turkish cotton and double that of Indian cotton.

- Egyptian cotton varieties can offer micronaire as low as 3.05 (Giza 45) and 3.24 (Giza 87) introducing maximum fineness which is not available in other varieties.

- Due to superior uniformity and cellulose distribution, Egyptian cotton introduces more comfort products, better absorption for dye material, better fabric breath while usage and durable appearance, which cannot be introduced with other varieties for lack of similar mechanical properties of Egyptian cotton.

References

- Comparison of Quality Characteristics of Yarns Spun from Aegean Cotton Fibres and Their Mixtures with South-East Anatolian Cotton Fibres – Dokuz Eylul University, Department of Textile Engineering – 2003.

- Central Institute for Cotton Research (CICR) – KHARIF SOUTH REPORTS 2006.

- Egyptian Cotton Arbitration Report – June 2007.

- SWICOFIL TEXTILE SERVICES – Cotton Research & Development – Switzerland.